Suzhou Zhiguan Yisheng Information Technology Co., Ltd. has been committed to the Internet of Things since its inceptionRFIDResearch and implementation of industry application technology. For years of service1000+Home to all types of customers.

withRFIDprinter, code and printRFIDtag

According to thefeedKey to make sure the paper runs correctly

Then you need to proceedRFIDPosition calibration, which can be operated in the printer panel:

^XA^HR^XZ

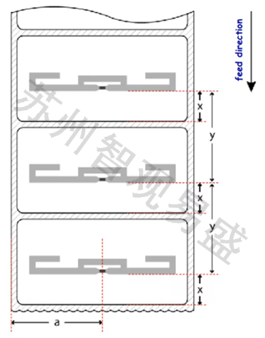

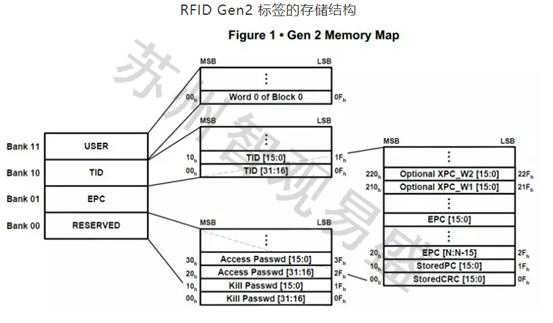

Next we need to look at the tag and understand some of the following parameters.

a RFIDDistance from the chip to the left edge

y RFIDChip to the nextRIFDThe distance of the chip

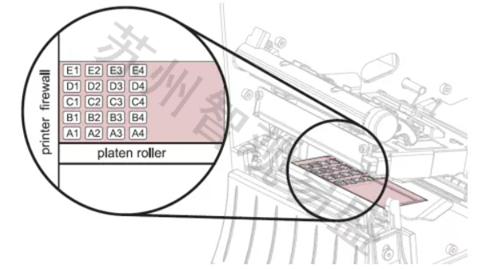

zebra Inside is an antenna array that selects the appropriate antenna number when the tag is corrected. Such as"A3" "B4"

Spacing less than26mmParameters of the label (right picture)yThe printer may need to send back a short distance before encoding. If necessary,RFIDCalibration will automatically select the reverse recoil distance.

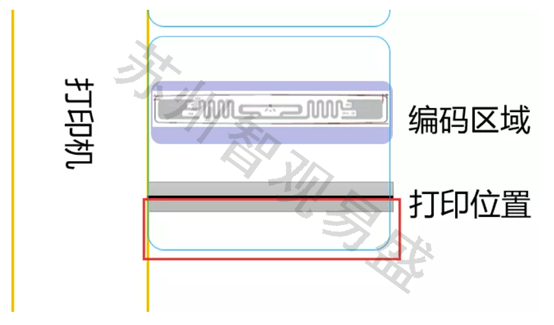

RFIDThe position of the inlay in the label has an effect on the print area.

Relative mode forward:

Relative mode backward:

Byy = B0 to B30 (In millimeters, the longest 30 Millimetre) . Move the media backwards before reading or encoding yy millimeter

We need something familiarZPLInstructions:

^RF For reading and writingRFIDtag

^HR calibrateRFIDTag position

^RS SettingsRFIDargument

^RW read-writeRFPower level

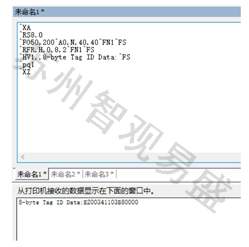

Example 1: ReadGen2 in-labelTAG EPCThe data is printed on the label

^XA

^FO50,50^A0N,40^FN0^FS

^XZ

The result is printed on the label and returned toRFIDprinter Host. Result for use "8-byte Tag ID Data" The header is marked.

^XA

^RS8,0

^FO50,200^A0,N,40,40^FN1^FS

^RFR,H,0,8,2^FN1^FS

^HV1,,8-byte Tag ID Data:^FS

^XZ

Printer output effect

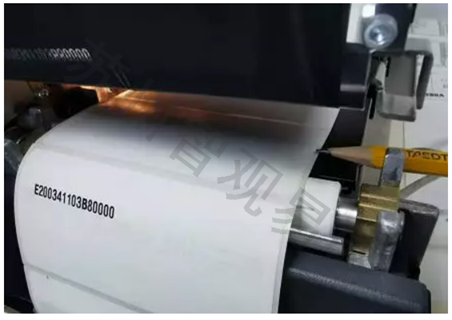

Attention:

When the label is encoded, if the label part already has more than a print head, the previous area in the red box cannot be printed, because the label will not be rolled back after encoding.

SATO CL4NX Metal resistant RFID printer

Warehouse management using RFID fixed asset system before and after comparison