Current Situation and Problems of Steel Structure Management

-

-

-

Our products are all stored in outdoor yards, with a relatively large range, making it quite difficult to find products that need to be shipped out. Do you have any experience in this area? The use of RFID technology to manage the inventory of steel structures is also a typical case that we have implemented frequently. The disorderly stacking poses great difficulties for on-site operators.IVES has designed a set of solutions specifically for such application scenarios and has successfully implemented them in multiple companies.

-

Our steel structures are only semi-finished products, and many of them are still occupying the storage yard due to improper management until scrapped. Do you have any way to avoid this situation? We not only manage the location of your steel structure products in the yard, but also bind each product with its corresponding finished product as a one-to-one or one-to-many identity, ensuring the utilization rate of semi-finished products and product delivery time, improving the flow rate and utilization rate of the yard, and enabling every product to be traceable.

-

Does your business scope cover all parts of the country? How to ensure your after-sales service? We are the gold medal agent of Zebra, and all products sold have a warranty period and comprehensive maintenance. Our software is independently developed.

IVES·Advantages of Steel Structure Management System

Utilizing powerful RFID technology to provide a comprehensive solution for quality management, process control, and workshop scheduling of steel structures

-

Geographic positioning of steel structures●Utilizing RFID technology to geolocate steel structures, allowing management and on-site operators to quickly and accurately locate steel structures.

Geographic positioning of steel structures●Utilizing RFID technology to geolocate steel structures, allowing management and on-site operators to quickly and accurately locate steel structures.

-

Automatic inventory of raw materials/inventory/products●The frequency of raw material and inventory inventory inventory can be increased, allowing for a more timely and accurate understanding of inventory conditions.●Products under monitoring can be automatically counted and generated into inventory lists without human intervention.

Automatic inventory of raw materials/inventory/products●The frequency of raw material and inventory inventory inventory can be increased, allowing for a more timely and accurate understanding of inventory conditions.●Products under monitoring can be automatically counted and generated into inventory lists without human intervention.

-

Automation of product production management●After the completion of steel structure production, the system automatically issues instructions to quickly process the next product.●Seamless integration to form Mini ERP: Associate with work orders in the ERP system, timely understand the production progress of products, and have a clear understanding of the overall plan of work orders.

Automation of product production management●After the completion of steel structure production, the system automatically issues instructions to quickly process the next product.●Seamless integration to form Mini ERP: Associate with work orders in the ERP system, timely understand the production progress of products, and have a clear understanding of the overall plan of work orders.

-

Clear understanding of product trends●Using IoT RFID sensing technology, 1-to-1 identity binding is applied to steel structure products, clearly grasping the entry, retention, and departure times of the product's location.

Clear understanding of product trends●Using IoT RFID sensing technology, 1-to-1 identity binding is applied to steel structure products, clearly grasping the entry, retention, and departure times of the product's location.

-

Timely adjustment of product utilization level●Timely adjust the utilization of products based on the retention time and status, reduce the production cost of steel structures, and improve the reuse rate

Timely adjustment of product utilization level●Timely adjust the utilization of products based on the retention time and status, reduce the production cost of steel structures, and improve the reuse rate

-

Efficient data query processing●Can query the detailed data of each functional node and print or export it.●When customers need to know the delivery date of their order accurately, sales personnel respond promptly and accurately through reports.

Efficient data query processing●Can query the detailed data of each functional node and print or export it.●When customers need to know the delivery date of their order accurately, sales personnel respond promptly and accurately through reports.

-

Connect and interact with mainstream data systems●Data interaction with ERP systems such as SAP, UFIDA, Dingjie, and Kingdee.

Connect and interact with mainstream data systems●Data interaction with ERP systems such as SAP, UFIDA, Dingjie, and Kingdee.

-

System functions can be optimized as needed●Easy to expand new functions and modules based on your changing needs.

System functions can be optimized as needed●Easy to expand new functions and modules based on your changing needs.

High performance RFID hardware configurationAchieve RFID tag reading accuracy of 99.99%

IVES·Helping You Control the Real Time Flow of Enterprise Asset InformationStock code: 900292

Geographic positioning of steel structures

Geographic positioning of steel structures Automatic inventory of raw materials/inventory/products

Automatic inventory of raw materials/inventory/products Automation of product production management

Automation of product production management Clear understanding of product trends

Clear understanding of product trends Timely adjustment of product utilization level

Timely adjustment of product utilization level Efficient data query processing

Efficient data query processing Connect and interact with mainstream data systems

Connect and interact with mainstream data systems System functions can be optimized as needed

System functions can be optimized as needed RFID Printer

RFID Printer Handheld RFID readers

Handheld RFID readers Fixed RFID readers

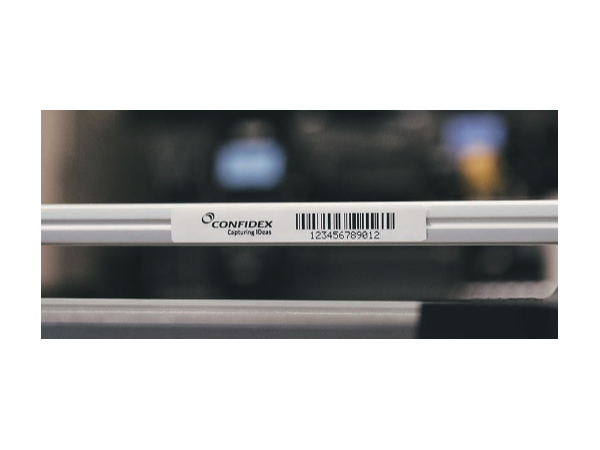

Fixed RFID readers RFID labels

RFID labels

RFID Steel Structure Traceability System

RFID Steel Structure Traceability System