-

-

-

To what extent can RFID technology be applied in warehouse management? Automatic entry and exit, automatic inventory, automatic data collection, and communication with the enterprise's ERP system data.

Sitting in the office, you can query real-time inventory data and the entry and exit details of various warehouse products with just one click, optimize the structure of inventory products, save storage costs of inventory products, and accelerate the operation of inventory products occupying funds.

-

Are you the one responsible for network wiring, hardware installation, and software development? We are the gold medal agent of Zebra. We have our own software development team, on-site construction team, and project manager. Our team has been working together for nearly 20 years and can provide you with an overall solution, avoiding the risk of multiple suppliers shifting responsibilities during the implementation process, bypassing various agents, and reducing your procurement costs.

-

A set of warehouse management systems is quite expensive. Is it more expensive for you to provide an overall solution? Based on your specific situation, we provide various versions of software to meet your budget and usage needs. You can easily have a warehouse management system for $20k.

IVES·Advantages of RFID warehouse management system Automatic inbound and outbound, greatly improving work efficiency

-

One item, one code

Products or raw materials have clear identity binding

01

-

Accurate search for goods

Effectively improving sorting and shipping efficiency and accuracy

02

-

1 second quick inventory

Long distance data reading does not require manual counting

03

-

Visual monitoring

Improve inventory turnover and warehouse utilization

04

Analysis of on-site warehouse management issues in production oriented enterprisesInventory backlog leads to a decrease in cash flow turnover speed of enterprises

-

-

-

(1) Different departments have different standards for defining basic information such as materials, which leads to a lack of attention when recording.

-

(2) Unable to quickly and accurately obtain material demand, making it difficult for the procurement department to control the upper and lower limits of procurement.

-

(3) Data sharing and low level of informatization often result in information asymmetry, which increases communication costs and reduces work efficiency.

-

(4) At present, the collection of many basic data is still limited to manual recording, making it difficult to conduct accurate and timely statistical analysis.

-

-

-

(1) High error rate in manual recording, such as inconsistent quantity filled in, inconsistent material names, etc.

-

(2) Different departments will repeatedly record data, resulting in an increase in labor volume.

-

(3) The data manually recorded by different departments varies greatly and is difficult to trace.

-

(4) Manual recording ultimately requires a high labor cost to statistically analyze warehouse turnover and other data.

-

-

-

(1) Many enterprises' materials will occupy the main channel, and the main materials will pile up in congested areas, making it difficult to ship out. At the same time, it also increases the security of inbound, outbound, and inventory.

-

(2) The warehouse cannot grasp the inventory status of surplus and unused materials. These leftover materials can also lead to inventory backlog and resource waste.

-

(3) Purchasing based on book inventory may lead to out of stock, resulting in excessive purchasing and accumulating over time, leading to an increasing backlog of inventory.

-

-

-

(1) The manual recording method and non-standard warehouse management have led to a significant difference between the actual inventory and the book inventory quantity. Making warehouse management very chaotic.

-

(2) The increase in backlog inventory reduces the speed of enterprise capital turnover, leading to an increase in production costs.

-

(3) A large amount of repetitive labor and inefficient data sharing have led to an increase in communication costs for enterprises.

-

(4) The increase in communication costs and production costs directly leads to a decrease in profits.

IVES · RFID System Solution Fully covering warehouse material management requirements

-

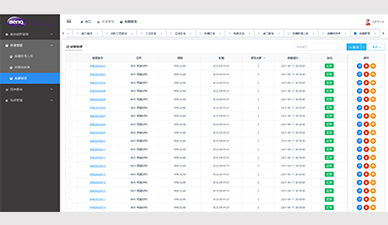

Complete warehousing function module●The comprehensive pre warehousing and pre outbound functions simplify complex tasks, improve the efficiency of warehousing and accuracy of shipment, reduce the risk of personnel turnover, reduce the risk of customer claims, and enhance customer competitiveness.

Complete warehousing function module●The comprehensive pre warehousing and pre outbound functions simplify complex tasks, improve the efficiency of warehousing and accuracy of shipment, reduce the risk of personnel turnover, reduce the risk of customer claims, and enhance customer competitiveness.

-

Multi warehouse classification management●Classify and manage raw materials, auxiliary materials, and finished product warehouses, and flexibly differentiate and integrate them.

Multi warehouse classification management●Classify and manage raw materials, auxiliary materials, and finished product warehouses, and flexibly differentiate and integrate them.

●Flexible allocation management between multiple companies and regions.

-

Unlimited hierarchical storage location management●Each storage location must correspond to a storage area, and each storage location can also be divided into whole material storage locations, zero material storage locations, stocking storage locations, general storage locations, etc. according to the purpose of use, which is conducive to the on-demand allocation and use of storage locations.

Unlimited hierarchical storage location management●Each storage location must correspond to a storage area, and each storage location can also be divided into whole material storage locations, zero material storage locations, stocking storage locations, general storage locations, etc. according to the purpose of use, which is conducive to the on-demand allocation and use of storage locations.

-

Visual statistical report●Inventory reports, inventory reports, inventory reports, etc. can query the detailed data of each node, and can be printed or exported.

Visual statistical report●Inventory reports, inventory reports, inventory reports, etc. can query the detailed data of each node, and can be printed or exported.

-

Intelligent warning reminder●Provide alerts for safety inventory and expired storage time, covering all process stages such as expiration alerts, inventory cycle alerts, and illegal outbound alerts, to improve warehouse turnover and inventory utilization.

Intelligent warning reminder●Provide alerts for safety inventory and expired storage time, covering all process stages such as expiration alerts, inventory cycle alerts, and illegal outbound alerts, to improve warehouse turnover and inventory utilization.

-

Seamless integration of various ERP systems●Through many successful cases, fully grasp the seamless integration of ERP system interfaces such as SAP, UFIDA, Dingjie, and Matman. Provide solid and reliable warehouse detail data for enterprise ERP.

Seamless integration of various ERP systems●Through many successful cases, fully grasp the seamless integration of ERP system interfaces such as SAP, UFIDA, Dingjie, and Matman. Provide solid and reliable warehouse detail data for enterprise ERP.

High performance RFID hardware configurationAchieve RFID label reading accuracy of 99.99%

IVES·Helping You Control the Real Time Flow of Enterprise Asset InformationStock code: 900292

Complete warehousing function module

Complete warehousing function module Multi warehouse classification management

Multi warehouse classification management Unlimited hierarchical storage location management

Unlimited hierarchical storage location management Visual statistical report

Visual statistical report Intelligent warning reminder

Intelligent warning reminder Seamless integration of various ERP systems

Seamless integration of various ERP systems RFID Printer

RFID Printer Handheld RFID readers

Handheld RFID readers Fixed RFID readers

Fixed RFID readers RFID labels

RFID labels